Hot keywords: wire forming machine/bending machine | looping machine/rounding machine/circling machine | looping butt welding machine

|

Product Details

Position:

Home>

Product Details

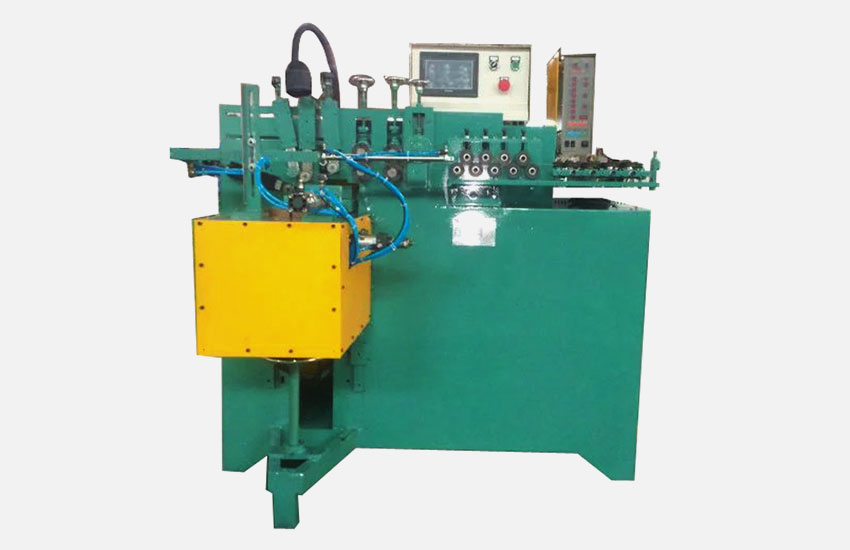

Circular butt welding machine

1. Resistance welding is to use electrodes to pressurize the weldment while energizing, and use the Joule heat (instantaneous) generated by the contact resistance between the electrodes to melt the metal to achieve the purpose of welding. No need to add any solder, high efficiency and low cost. Easy to automate and other features. 2. It adopts pneumatic vertical pressurization and upsetting system, with high pressure, reliable clamping of the workpiece, and sufficient rigidity of the machine body. 3. The welding transformer is made of T1 copper, imported high-permeability silicon steel sheet, epoxy resin vacuum casting, and forced cooling with water inside the secondary, and is optimized and carefully manufactured. The no-load loss is extremely low, the power output is strong and stable, the insulation level is high, and the service life is long. The dual-channel monitoring of the transformer temperature rise can effectively prevent the adverse consequences of high temperature damage caused by overload use. 4. The equipment is controlled by a microcomputer controller, with clear programming, intuitive display, optimized control of the entire process of pre-pressing, pre-heating, upsetting, tempering, holding, and rest, and high welding accuracy. 5. SCR heating monitoring and multiple protection functions. 6. It is widely applicable to butt welding of low carbon steel, alloy steel, non-ferrous metal pipe fittings, capillary tubes, bars, plate profiles and dissimilar metals.

|