Hot keywords: wire forming machine/bending machine | looping machine/rounding machine/circling machine | looping butt welding machine

|

Product Details

Position:

Home>

Product Details

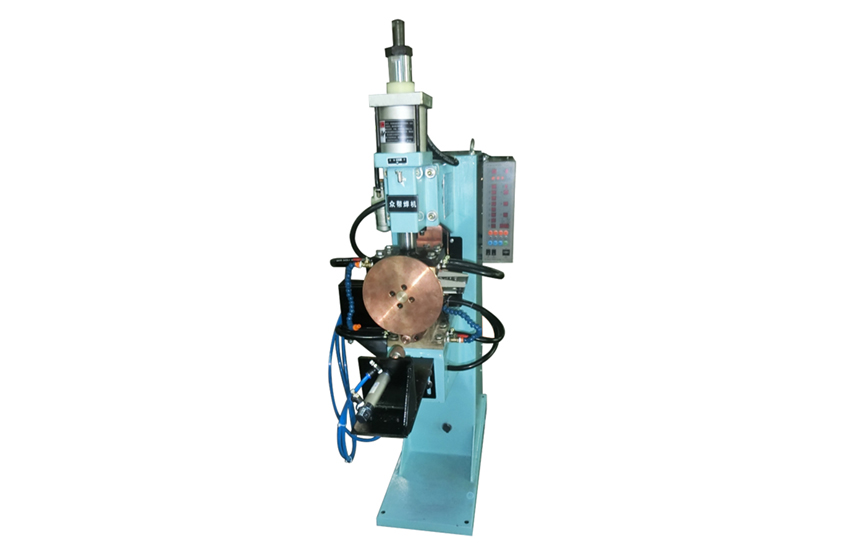

Double roller seam welder

Introduction The seam welding machine is evolved from the resistance welding machine. It is divided into upper and lower double electrode rollers and single rollers, other types of special machines and other types of welding equipment. According to the longitudinal and transverse seams, some are also called longitudinal seam welding machines, Horizontal seam seam welding machine.

1. The use of seam welding machine The seam welding machine is mainly used for butt welding of carbon steel and stainless steel circular workpieces. According to specific requirements, single seam seam welding machine or double seam seam welding machine can be selected. Compared with the vertical girth seam welder, there is no too much restriction on the length of the weldment. Long pipes of three or four meters can be welded easily. Roll welding machines can be widely used in the welding of hydraulic oil cylinders, automobile steering racks, transmission shafts, gas storage cylinders, chemical and medical containers, liquefied gas tanks, fire fighting equipment, rollers and liquid storage cylinders for mines and production lines. 2. The main configuration and functions of the circumferential seam seam welding machine Bed structure: Welded structure to ensure the rotating diameter of the workpiece and the strength of the bed. The bed is heat treated. The roller is relatively fixed, the workpiece rotates, and the welding position is horizontal. The workpiece is clamped and moved by a three-jaw chuck, with a lifting support mechanism in the middle. Spindle box: The spindle is equipped with a gap fine-tuning device to effectively adjust the spindle runout after the bearing is worn. The radial and end runout of the spindle is less than 0.15mm. The coaxiality between the tailstock and the main shaft is less than 0.15mm. Workpiece support: using linear guides, the position and height of the first work piece is manually adjusted, and the rise and fall are automatically controlled after adjustment. The workpiece support mechanism can move longitudinally along the guide rail to adapt to the welding of workpieces of different lengths. Roller system: motor driven (automatic/manual), the height of each circle is adjustable. Anti-radiation light device: install the anti-radiation light door and close it manually when welding. Welding process: parameters can be set in layers (including rotation angle), continuous welding. The swing of the welding gun needs to have an automatic zero return function. The number of welding turns can be set from 1 to 10 turns. It has the function of high voltage, slow wire feeding and arc ignition to ensure reliable arc ignition; and the function of low voltage and low current to close the arc and fill the arc crater. Welding power supply: imported power supply, water-cooled welding gun, suitable for long-term welding. When the circulating cooling water tank does not start, an alarm will be issued and the welding function cannot be started. The PLC is used to control the coordination of the operation and action of the whole machine, as well as the rotation of the workpiece during the welding process, the swing frequency, swing amplitude, swing time of the welding torch, the automatic lifting time of the welding torch, the lifting distance, the number of lifting, etc. Welding gun swing and synchronous lifting adopt a stepping motor control system, welding length adopts closed-loop detection, and position detection adopts imported non-contact switch detection. At present, Zhongbang Welding Machine produces a variety of customized special machines, such as threaded inner tank seam welding machine, double-head inner tank seam welding machine, etc. Welcome to inquire and order. To learn more click on welding equipment Previous

|