Hot keywords: wire forming machine/bending machine | looping machine/rounding machine/circling machine | looping butt welding machine

|

Product Details

Position:

Home>

Product Details

New stainless steel flash butt welding machine

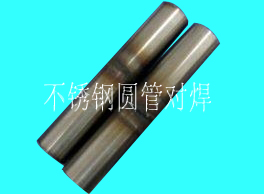

Brief introduction of flash butt welding machine Flash butt welding mainly uses the heat generated by the contact resistance of the workpiece to heat the workpiece, the metal surface is melted, the temperature gradient is large, and the heat-affected zone is relatively small. The weld is to form a common crystal grain under the condition of plastic deformation of the counterpart solid phase metal of the workpiece. The structure and composition of the weld are close to the basic metal (or after heat treatment), and it is relatively easy to obtain a welded joint of equal strength and plastic. The flash search process has the self-protection function of exhausting air and reducing metal oxidation. Upsetting can also discharge oxides with the liquid metal out of the weld. There are fewer defects such as weld inclusions and incomplete penetration. The flashing process has a strong self-adjustment function, and has low requirements for strict compliance with specifications, and the welding quality is stable. The unit welding cross-sectional area requires low electric power, and only (0.1-0.3) KVA/mm2 electric power is required for welding mild steel. Welding productivity is high, and it only takes a few seconds to tens of seconds to weld a joint. Welding has a wide range of applications. In principle, all metal materials that can be forged can be welded by flash butt welding. For example, low-carbon steel, high-carbon steel, alloy steel, stainless steel and other non-ferrous metals and alloys can be welded by flash butt welding. The welding cross-sectional area is wide, generally from tens to tens of thousands of mm2 cross-sectional area can be welded. Flash butt welding is widely used in welding various plates, pipes, profiles, solid parts, tools, etc. It is widely used and is an economical and efficient welding method. Welding sample display:

Return to the homepage and clickWelding equipment Previous

|