Hot keywords: wire forming machine/bending machine | looping machine/rounding machine/circling machine | looping butt welding machine

|

Product Details

Position:

Home>

Product Details

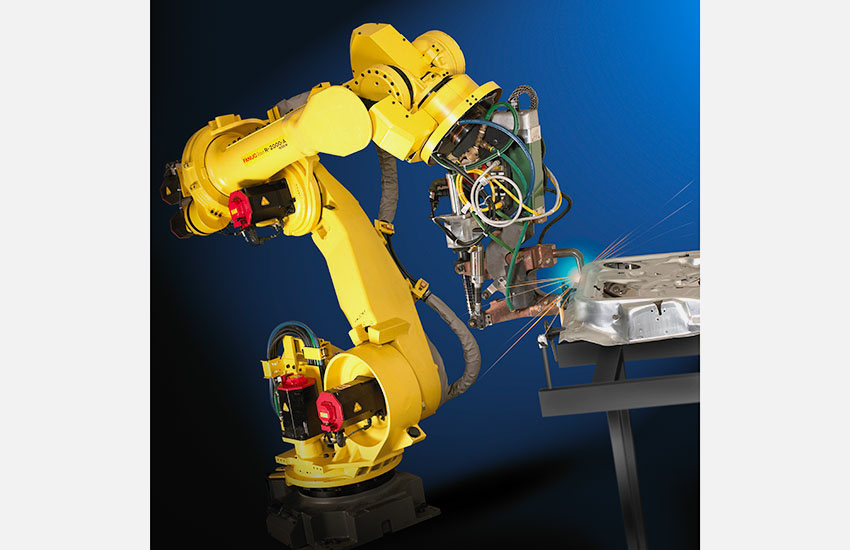

Welding Robot

Welding robots are also called welding manipulators. The radius can be set according to needs. Usually represented by the number of axes, the more the number of axes, the larger the welding radius. Welding robots are one of the stars of modern automated welding equipment, the traditional argon-fluorine welding , Carbon dioxide, oxygen welding, etc. will cause harm to the human body, so welding robots/welding manipulators are particularly important, and the efficiency is much higher than that of manual labor. Let’s talk about the classification of welding robots: a. Arc welding robot b. Spot welding robot

Features of arc welding robot: The arc welding process is more complicated than the spot welding process. The tool center point (TCP), that is, the movement path of the wire end, the posture of the welding gun, and the welding parameters require precise control. Therefore, in addition to the basic functions described above, the arc welding robot must also have some functions that meet the requirements of arc welding. Even though theoretically speaking, a 5-axis welding robot can be used for arc welding, it is more difficult to use a 5-axis robot for complex shapes of welds. Therefore, unless the weld is relatively simple, a 6-axis robot should be used as much as possible. Features of spot welding robot: Spot welding has relatively low requirements on the robots used. Because spot welding only needs to be mastered, there are no strict technical requirements for the moving path of the welding clamp between points. This is why welding robots can only be used for spot welding. Spot welding robots must not only have sufficient load-bearing capacity, but also must move quickly between points, the process must be stable, and the positioning must be accurate to reduce working time and improve the efficiency of the robotic arm. The load capacity that the spot welding robot needs to have depends on the style of welding gun used. For welding guns that are separated from the transformer, a robot with a load of about 40 kg is sufficient. However, on the one hand, this kind of welding tongs has a large power loss due to the long secondary cable, and it is also not conducive to the robot to extend the welding tongs into the workpiece for welding; on the other hand, the cable keeps moving with the robot, and the loss of the cable fast. Therefore, companies currently use integrated welding tongs. The weight of this welding tongs together with the transformer is about 75kg. Taking into account that the robot must have sufficient load-bearing capacity and be able to deliver the welding tongs to the space position at a faster acceleration for accurate welding, a heavy-duty robot with a load of about 130kg is generally used. In order to meet the requirements of the short-distance fastness of the welding tongs during continuous spot welding. The new heavy-duty welding robot adds the function of 5cm displacement within 0.3s. This puts forward advanced requirements for the quality of the motor, the calculation speed of the microcomputer and the algorithm. Zhongbang Welding Machine Factory provides a variety of robots, and you can contact by phone if you need it. Watch the video, you can search on Baidu: Zhongbang Welding Machine from the channel Related technical parameters of welding robot/welding manipulator:

Related resistance welding equipment: automatic gantry welding machine, xy-axis automatic row welding machine |